Aluminium powder is powdered aluminium.

Aluminium powders give the ultimate metallic leafing finish in resin. Using only a smalll amount into your resin mix you can achieve the most amazing of metal looking finishes. These powders give the ultimate metallic leafing finish in resin.

Furthermore aluminum powder as a raw material for the light weight concrete industry has been used since the beginning of the commercial manufacture.

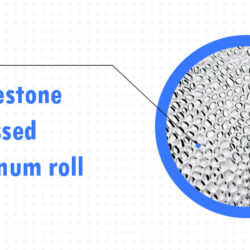

This was originally produced by mechanical means using a stamp mill to create flakes. Subsequently, a process of spraying molten aluminium to create a powder of droplets was developed by E. J. Hall in the 1920s. The resulting powder might then be processed further in a ball mill to flatten it into flakes for use as a coating or pigment.

Aluminium powder, if breathed in, is not particularly harmful and will only cause minor irritation. The melting point of aluminium powder is 660 °C.

How to Buy

Aluminium powder is sold in 250g, 1kg and 5kg pack sizes. Please choose the pack size you require from the drop-down list at the top of the page.

25kg packs are available on request; please contact us for pricing.

Further Information

How to Use

A ratio of at least 50% aluminium powder (by weight) would be required to result in a significantly metallic appearance. Higher ratios, up to the limit of pourability, will yield a more impressive metallic appearance and feel.

After casting, the metallic appearance will not be clear or vivid because the metal particles will be obscured behind a thin layer of resin. To reveal the metallic appearance, the casting can be rubbed with an abrasive pad or wire-wool.

When adding metallic powders to polyester or vinylester resin systems it is important to catalyse the resin prior to adding the metal powder so as to avoid any adverse reaction (rapid oxidisation) of the metal powder by the catalyst.

Such oxidisation or other adverse reactions are unlikely to occur with polyurethane or epoxy resins but it may still be a good idea to mix the resin and hardeners together before adding the metal powder.

Use In Cold-Casting / Resin Casting

Add copper powder to castings resins such as polyurethane Fast-Cast resins, polyesters or epoxies for an authentic metallic aluminium appearance and feel.

Added to the whole of the resin mix, aluminium powder will increase the density of a casting (making it feel heavier) as well as its thermal conductivity (making it feel colder). Alternatively, it can be added in higher ratios to only a thin surface layer by slush-casting or rotational-moulding, giving a very metallic surface to a casting that can then be back-filled with unfilled resin.

To Add Temperature Stability

Aluminium powder is very frequently added to resins and gelcoats in order to improve their dimensional stability, particularly for use at elevated temperatures.

Epoxy tooling gelcoats, laminating pastes and casting resins can all be filled with aluminium powder to improve their dimensional stability at high temperature.

The properties are those of the Aluminum Powders metal:

•

High thermal conductivity

•

Resistance to corrosion but hydrolysis by action of bases and water

•

Low density for a metal but higher than that of thermoplastics

•

Opacity and reflection of visible, infrared, and UV light

•

Electrical conductivity but high electrical resistance of the fine layer of alumina on the surface

•

Barrier properties versus gas and liquids

•

Ductility, weak mechanical resistance.

The extreme division of aluminum powders generates explosive risks.