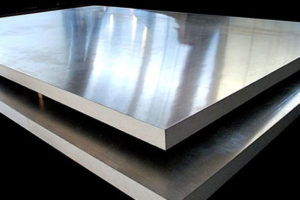

Both aluminium alloy 6061 plate and 6063 aluminium alloy belong to 6 series aluminum alloy. They are also the most commonly used grades in 6 series aluminum alloy plates. When it comes to the difference between them, the main difference is actually the difference in aluminum content and alloying elements, resulting in performance and There is a difference in terms of use.

The main alloying elements of 6063 aluminium alloy are magnesium and silicon. It has easy processing, excellent weldability, extrudability and electroplating, good corrosion resistance, toughness, easy polishing, superior coating, excellent anodizing effect, 6063 aluminum plate. It is a typical extruded alloy widely used in construction profiles, irrigation pipes, pipes, rods, profiles, etc. for vehicles, benches, furniture, lifts, fences, etc.

Although the main alloying elements of 6061 aluminium alloy are also magnesium and silicon, the difference is that the 6061 aluminum plate forms the Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad effect of iron; sometimes a small amount of copper or zinc is added to increase the strength of the alloy without significantly reducing the corrosion resistance; Copper to counteract the adverse effects of titanium and iron on conductivity; zirconium or titanium can refine grains and control recrystallized structure; in order to improve machinability, lead and antimony can be added. In Mg2Si, the Mg/Si ratio is 1.73. Under heat treatment, Mg2Si is solid-melted in aluminum, giving the alloy an artificial age hardening function.

6061 aluminum plate requires various industrial structures with certain strength, weldability and corrosion resistance, such as tubes, rods and shapes for the manufacture of trucks, tower buildings, ships, trams, furniture, mechanical parts, precision machining, etc. , plate.

In general, the 6061 aluminum plate has more alloying elements than the 6063 aluminum plate, so the material strength is higher than 6063 aluminum plate.