Fin production machines for aluminum radiators are main equipments in heat exchanger factory because fins are the key heat transfer elements.The fin making machine matched with different specification`s fin forming molds can automatically and stably produce all kinds of Heat Exchanger Fins. This series of Fin Forming Machines CPJG-300/450 are special for aluminum heat exchangers. Fin pitch for 5mm Max(one fin), fin flow length 300mm/450mm max. fin height for 12mm max. This series of high speed radiator fin forming machines with servo cutter are our standard equipments which also are most advanced and most popular at present in radiator factories. If your radiator fin is beyond the above fin specification, we also customize the Fin Machine and fin punching molds to meet your complete fin requirement. The fins via our Fin Forming Machine have many advantages of high precision, good appearance and low processing cost. Heat Exchanger Fin making machine is mainly made up of automatic feeding material Device, high speed automatic fin stamping machine, servo cutter of heat exchanger fins, radiator fin Forming Dies customized.

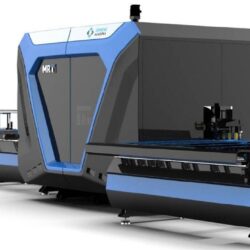

Fully automatic Aluminum Radiator Fin Machine 48mm Wide OEM Production

Summary

The fin machine is used to produce heat exchange wavy fins with or without windows.

The radiator fin machine is equipped with the following devices: decoiler, tensioning device, feeding, interval oil lubrication,

fin forming, correction and cuttig function, strip run-out detection, blockage detection device, cutting fault indicator, fin forming

unit overloading protection device, and fault indication light.

The radiator fin machine adopts PLC, inverter, AC servo control, and touch screen control. The parameters are easily set

through the touch screen.

II Main configuration of radiator fin forming machine

3.1 PLC: Delta from Taiwan

3.2 Inverter: Delta from Taiwan

3.3 Servo motor and driver: Delta from Taiwan

3.4 Approaching switch: Omron from Japan

3.5 Circuit breakers and leakage protector: Schneider from China

|radiator fin forming machine|radiator fin forming machine|radiator fin forming machine|radiator fin forming machine|

IV Documentary and spare parts of radiator fin forming machine

4.1 Operation manual

4.2 Electric wiring, pneumatic principle and lubricating drawings

4.3 Cutting blade: one

4.4 Special tools for rolling tooling: one set

|radiator fin forming machine|radiator fin forming mac