Air conditioning systems are essential for maintaining comfortable indoor environments, and aluminum plays a vital role in their construction. Aluminum’s favorable properties, such as its lightweight nature, corrosion resistance, and thermal conductivity, make it an ideal material for various components in air conditioners. Understanding the aluminum parts and alloys used in these systems can shed light on their functionality and efficiency. In this article, we will explore the common aluminum parts and alloys found in air conditioners, highlighting their significance in achieving optimal cooling and heating performance.

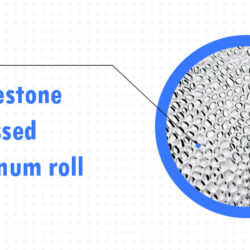

Aluminum fin

Aluminum is a commonly used material in various components of air conditioning systems due to its favorable properties. Some of the aluminum parts found in air conditioners include:

Heat exchangers: Aluminum is extensively used in the construction of heat exchangers, which are essential for transferring heat between the indoor and outdoor environments. Both the evaporator coil (indoor unit) and the condenser coil (outdoor unit) typically consist of aluminum tubing or fins.

Air conditioner cabinets: The outer casing or cabinet of an air conditioner is often made of aluminum or aluminum alloys. Aluminum is lightweight, corrosion-resistant, and easy to shape, making it suitable for constructing durable and aesthetically pleasing cabinets.

Fan blades: Aluminum is a popular choice for manufacturing fan blades in air conditioning units. It offers a good balance of strength, lightness, and corrosion resistance, allowing the fan to operate efficiently and quietly.

Tubing and piping: Aluminum tubes and piping are utilized in the refrigerant circuit of air conditioners to carry the refrigerant between various components. The lightweight nature of aluminum helps in reducing the overall weight of the system and facilitates easier installation.

Heat sinks: Air conditioners often incorporate heat sinks to dissipate excess heat generated by electronic components such as compressors and motors. Aluminum heat sinks provide excellent thermal conductivity and help in cooling these components efficiently.

Mounting brackets: Aluminum brackets are used for mounting and securing different parts of the air conditioning system. These brackets provide stability and support for the components, ensuring proper positioning and reducing vibration.

It’s important to note that while aluminum is widely used in air conditioning systems, there may be variations in the specific components depending on the design, model, and manufacturer of the unit.

Aluminum alloy in Air Conditioning Systems

What are the Different Grades or Alloys of Aluminum Used in Air Conditioning Systems?

There are different grades and alloys of aluminum used in air conditioning systems, depending on the specific requirements and components involved. Here are some common grades and alloys used:

Aluminum 1100: This is a commercially pure aluminum grade that offers good corrosion resistance and excellent formability. It is often used for aluminum fins in heat exchangers due to its ease of shaping and high thermal conductivity.

Aluminum 3003: This alloy contains small amounts of manganese, making it stronger than pure aluminum. It is commonly used for aluminum tubing in heat exchangers due to its good formability, corrosion resistance, and moderate strength.

Aluminum 5052: This alloy includes magnesium as the primary alloying element, providing improved strength and better resistance to corrosion. It is often used for air conditioner cabinets and components that require higher strength and durability.

Aluminum 6061: This alloy is known for its excellent strength-to-weight ratio, making it suitable for applications that require both strength and lightness. It is sometimes used in air conditioning system brackets or structural components.

Aluminum 6063: This alloy offers good extrudability and is commonly used for extruded components, such as aluminum frames for air conditioner units. It has moderate strength, and corrosion resistance, and can be easily formed into complex shapes.

These are just a few examples of aluminum grades and alloys used in air conditioning systems. The choice of grade or alloy depends on factors such as the specific application, desired strength, corrosion resistance, and manufacturability requirements. Manufacturers carefully select the appropriate aluminum material to ensure optimal performance, longevity, and cost-effectiveness of the air conditioning components.

Conclusion

In conclusion, aluminum parts and alloys are integral to the efficient functioning of air conditioners. From heat exchangers and tubing to fan blades and cabinets, aluminum’s unique properties contribute to the overall performance and longevity of these systems. The use of specific aluminum alloys, tailored to meet the requirements of different components, ensures optimal strength, corrosion resistance, and thermal conductivity. As advancements