Size Specifications

The width of the prepainted steel coils must have an allowable error of ±2mm.

The cutting line should be straight and the cut surface should be neat.

The thickness tolerance is ±0.03mm.

Coating Requirements

The type of coating applied must meet the specified requirements in the contract.

The color of the coating should be uniform without any noticeable differences.

The thickness of the coating should comply with the specifications laid out in the contract.

Surface Inspection

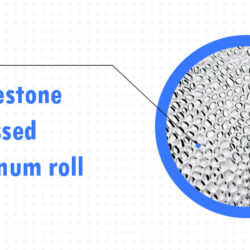

The surface of the coils should be flat and free from visible unevenness, warping, or deformation.

There should be no oil contamination, surface bubbles, shrinkage cavities, or any other defects that could negatively impact their use.

The defective portion of each coil should not exceed 5% of the total length, and there should be no noticeable scratches, bumps, or scars.

Labeling Requirements

The packaging must include clear and conspicuous markings with the product name, specification, and manufacturer.

The packaging mark should also feature the supplier’s name or trademark, standard number, grade, specification, and weight.

An identification number that can trace the steel to its smelting origin should be indicated on the packaging.

The quality certificate should include the buyer’s name, contract number, product name, standard number, specification, grade, identification number, weight, number of pieces, production date, and delivery date.

The mark should also clearly state the weight of the substrate coating, type of finish, and color.