The more commonly used anodised aluminium grades are 1060 aluminum plate, 5052 aluminum plate, 6061 aluminum plate, 6063 aluminum plate and 7075 aluminum plate. Anodised aluminium plate is much stronger than ordinary aluminum plate, whether it is smoothness or flatness, it is better than ordinary aluminum plate. The main reason is that the production process of the anodized aluminum plate is more exquisite, especially the surface treatment.

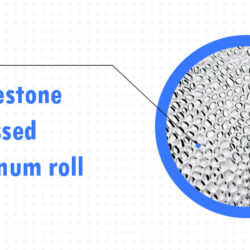

The anodised aluminium grades are 1000 series, 3000 series, 5000 series, 6000 series and 7000 series. The processing of anodized aluminum plate product are: the aluminum plate is hanged – degreasing – alkali etching – neutralization – chemical polishing – neutralization – anodizing – dyeing – sealing – baking – drying – hanging – inspection – packaging and other series of processes, a thick and dense oxide film layer is formed on the surface of the aluminum plate to significantly change the corrosion resistance of the anodized aluminum alloy, improve the hardness, wear resistance and decoration performance. The color of anodized aluminum plate is much richer, which is more conducive to our requirements for color, especially the exterior decoration of buildings, which is why aluminum plate processing enterprises like this anodised aluminum plate product.

The surface of the anodised aluminium grades plate is anodized, that is, an insulating layer grows on the surface, which is an inseparable part of the aluminum plate itself, it is rich in metallic luster, and the oxide film will never fall off. The anodized aluminium plate is non-conductive, safe and environmentally friendly. The anodized aluminium sheet product has passed the SGS environmental protection system certification, and has strong corrosion resistance, scratch resistance, the surface hardness reaches sapphire level, and is resistant to washing; the surface gloss is uniform and the oxide layer will never fall off.