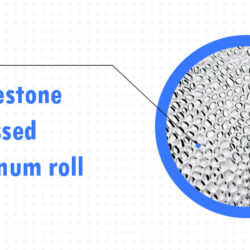

Aluminium is incredibly reactive and so develops a very (as in VERY) thin oxide layer more or less as soon as it is made or reshaped. What looks like a super-shiny metal on a roll of foil is in fact the oxide with metal showing through.

Some metals are more reactive than others and Aluminum is far more energetic to oxidize than iron. Yes, aluminum is faster to rust than iron. The roll of aluminum foil you get in the store is already rusted before you use it.

So why does it still look shiny? Aluminum forms aluminum oxide. This is an extremely hard material that forms a layer on the surface that is only a few molecules thick. It then prevents more oxygen from getting to the pure aluminum below the oxide layer.

In contrast, iron forms ferrous oxide, a reddish orange material that is very porous. This means that the outer layer of iron is ripped away to form ferrous oxide, and because it is porous, oxygen can continue to penetrate to the iron, creating more rust. Some of the ferrous oxide converts to ferric oxide, a black material, so the resulting rust mixture can be various shades of brown. Eventually, the entire iron object will be converted to rust.

One final point to demonstrate how much stronger aluminum likes oxygen more than iron does. If you mix ferric oxide powder with aluminum powder, you have something called thermite. This can be used for welding or burning holes in tanks. It is also the fuel used in the space shuttles booster rockets (although they use ammonium perchlorate instead of rust). Once ignited, the aluminum oxide layer on the powder is disrupted releasing pure aluminum. The aluminum rips the oxygen away from the ferric oxide to produce aluminum oxide and pure iron. And heat; a lot of heat. That energy release is the measure of how much more reactive aluminum is compared to iron.

The aluminum foil in stock of the company will appear to be oxidized and white spots when placed for a long time. How to prevent this phenomenon?

- The storage environment of aluminum foil should be dry, bright, well ventilated and non-corrosive.

- Aluminum foil rolls should be kept away from rain and snow.

- Strengthen the management of aluminum foil rolling oil, and its water content is controlled below 0.04%.

- The packaging of aluminum foil rolls should be sealed and the appropriate amount of desiccant should be placed in each roll.

- The aluminum foil coil is transported from the low temperature zone to a place with high temperature and high humidity. Do not open the package immediately.