Aluminum bronze is a type of copper alloy in which aluminum is the primary alloying element added to the copper. This stands in contrast to standard bronze or brass, in which the alloying elements are tin and zinc, respectively. Aluminum enhances copper by imparting oxidation resistance in the form of a thin, tightly adherent aluminum oxide film. Other metals such as manganese, nickel, silicon, and iron can be added to aluminum bronze to further enhance strength or anti-corrosive properties.

The manufacturing process for creating aluminum bronze is similar to the techniques involved for other copper alloys. First, the copper element is heated to a predetermined temperature. Once the copper is in its molten state, specified amounts of aluminum are added (in addition to other alloying elements, which will depend on the type of alloy desired). The molten mixture is then poured into the mold for the specific component and allowed to cool.

Types of Aluminum Bronze

There are numerous types of aluminum bronze as categorized by the Unified Numbering System (UNS), developed by American Society for Testing and Materials (ASTM) and Society of Automotive Engineers (SAE). These alloys differ mainly based on the amount of primary element (aluminum) and the number of secondary elements alloyed with the copper.

The various types of aluminum bronze are defined in the UNS using reference numbers ranging from C95200 to C95800. For instance, C95200 aluminum bronze contains 8.5% to 9.5% aluminum by weight, while C95300 contains 9.0% to 11.0%

Although there are dozens of aluminum bronze alloys available, they can all be classified into four principal types:

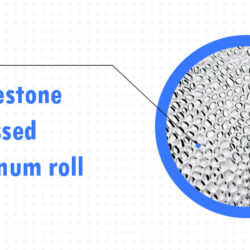

Low-alloy, single-phase alloys — These alloys contain less than 8% aluminum and have excellent cold ductility properties, making them ideal for cold working into tubes, strips, sheets, and wires.

Moderately alloyed, two-phase (duplex) alloys — These alloys contain 8% to 11% aluminum and small amounts of other elements added for higher strength properties. These materials are suitable for hot working applications. Aluminum bronze casting is also a popular method for working these alloys.

Copper-aluminum-silicon alloys, or silicon-aluminum bronzes — These alloys contain up to 6% aluminum and 2% silicon. Similar to other bronzes, these materials have low magnetic permeability as well as exceptional resistance to shock and vibrational loading.

Copper-manganese-aluminum alloys, or manganese-aluminum bronzes — Unlike other aluminum bronzes, manganese is the primary alloying element by weight (approximately 13%) in these materials, while aluminum makes up about 8% to 9%. Although these alloys do not possess the same strength properties as the other types, they have excellent resistance to impingement, cavitation, and wear.

Common Aluminum Bronze Alloys And Some Typical Applications:

C95200 is a highly ductile material with good corrosion resistance. This is ideally suited for bushings, bearings, light duty gears, wear plates, low-pressure piping, pump columns, and containers.

C95400 offers high yield and tensile strength, extraordinary toughness, and exceptional resistance to wear, fatigue, and deformation. This all-purpose alloy is widely used in chemical, marine, aircraft, and machine tools as gears, bushings and bearings, pumps, and valves.

C95500 is one of the toughest of the non-ferrous alloys. It serves the same industries as C95400 with higher strength, hardness, and corrosion resistance, though it has a slightly lower impact toughness.

As a special Nickel Aluminum Bronze, C95800 is especially suited for marine applications with optimum resistance to seawater corrosion. Those may include propeller system parts, bushings, bearings, piping, including desalination, and other corrosive marine applications.

C95900 provides higher hardness and compressive strength, and is used for wear plates, forming rolls, draw dies, gears, valve guides, seats, and die inserts.

MTEK 375 is an extremely hard, superior material often used for forming, drawing, and bending stainless steel

Naval Applications

C63200 Bronze is a very common sight in the naval industry, for both the civilian and military sectors. You can often see its use in drive shafts for marine vehicles. Naval vehicles, especially submersibles, often undergo heavy amounts of force and pressure. Because Aluminum Bronze C63200 is so strong, it’s often chosen for military applications in the naval forces. The added corrosion resistance allows it to better withstand the seawater, making the need for repairs much less frequent.

Industrial Applications

Given Aluminum Bronze C63200’s very high resistance to wear and tear damage, it is also a commonly used metal in the industrial sector as well. Industries that deal with seawater benefit from its corrosion resistance in the same way that naval vehicles do. It’s a reliable metal that can be used in many different applications such as:

Valve stems

Shafts

Cams

Bearing cages

Sea water pump bodies and valves

Fasteners

One of the more specific applications for Aluminum Bronze C63200 is its use in industrial fasteners. These tend to require extremely strong metals that can withstand a lot of force all at once, which C63200 Bronze is known for.