Scrap metal recycling is the process of reclaiming metals from manufactured items for use in new products. Collection is merely the first step in metal recycling; once recyclable metals have been collected, they will go through additional sorting and treatment before recycling begins.

Sorting

In most cases, scrap metal is not sorted prior to collection. Thus, the first step in scrap metal recycling after collection is sorting. This step includes demolition or dismantling of appliances and other items so they can be broken down into their individual components. Because iron is magnetic, iron components can be sorted from other metals using a magnet, after which they are separated for processing. Non-ferrous metals are sorted using other properties, such as weight and color.

Cleaning

Metal meant for recycling must also be cleaned to remove materials such as paper, paint, food particles, dirt, and other potential contaminants. Even metals that have been rinsed prior to recycling are cleaned after sorting. Cleaning is an important part of the recycling process, as contaminants will affect the quality of the recycled product if they are not removed first.

Recycling

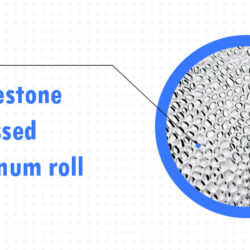

The actual process of recycling metals occurs when the metals are broken down and reformed into usable pieces, called ingots. Different metals may go through various recycling processes, based on their properties. Tin is bathed in a saline solution and an electric current is applied, which collects the tin onto one of the two electrical plates. The tin is then melted and cast into ingots for manufacturing. By contrast, aluminum is typically shredded prior to melting, after which it is cast into ingots and delivered to a manufacturing plant for reuse.

Cooling and shaping

Once the purity of the metal has been confirmed, the melted scrap metals will be cooled and shaped into bars for easy transportation. The bars are then sold to manufacturers all around the world to be created into new products and when those products reach the end of their useful lifespan, the whole process begins all over again.

Melting

Once the metal is thoroughly sorted according to type, recycling firms will then prepare the scrap for melting. This typically involves shredding the metal to ensure that pieces are uniform in size and small enough to melt quickly. Metals are melted in a large furnace, the temperature of which varies based on the type and volume of the metal being melted. After the metals are melted they will be tested for purity to ensure they’re free from contaminants.