Aluminium oxide is a chemical compound of aluminium and oxygen with the chemical formula Al2O3. It is the most commonly occurring of several aluminium oxides, and specifically identified as aluminium(III) oxide. It is commonly called alumina and may also be called aloxide, aloxite, or alundum depending on particular forms or applications. It occurs naturally in its crystalline polymorphic phase α-Al2O3 as the mineral corundum, varieties of which form the precious gemstones ruby and sapphire. Al2O3 is significant in its use to produce aluminium metal, as an abrasive owing to its hardness, and as a refractory material owing to its high melting point.

Chemical Properties

There are many different forms of aluminum oxide, including both crystalline and non-crystalline forms. The chemical formula for Aluminum Oxide is Al₂O₃. It’s an electrical insulator, which means it doesn’t conduct electricity, and it also has relatively high thermal conductivity. In addition, in its crystalline form, corundum, its hardness makes it suitable as an abrasive. The high melting point of aluminum oxide makes it a good refractory material for lining high-temperature appliances like kilns, furnaces, incinerators, reactors of various sorts, and crucibles.

chemical formula for aluminum

Aluminium Oxide Nanoparticles

Aluminium oxide nanoparticle’s antimicrobial activity is due to the attachment of the nanoparticles to the surface of the bacterial cell, resulting in cell death . There are few reports on the antimicrobial activity of aluminium oxide nanoparticles. Jalal et al. synthesized aluminium oxide nanoparticles using Cymbopogon citratus leaf extract. The nanoparticles perforated Candida cells, disrupting the morphological and physiological activity of the cells, thus resulting in cell death [61]. Ansari et al. prepared aluminium oxide nanoparticles using leaf extracts of lemongrass [63]. Their antibacterial activity against extended-spectrum lactamases and metallo-lactamases of clinical isolates of P. aeruginosa was found to be notable

Other researchers also described similar antibacterial activity of aluminium oxide nanoparticles toward gram-positive and gram-negative bacteria . The antibacterial activity of the nanoparticles was suggested to be due to a combination of factors such as the cationic size of nanoparticles, formation of reactive oxygen species, and self-promoted uptake mechanism of the nanoparticles over the outer membranes of bacteria resulting in cell death Sadiq et al. suggested that aluminium oxide nanoparticles do not possess extreme antimicrobial activity, even at higher concentrations, describing that the nanoparticles have very mild toxicity toward a few selected strains of bacteria . Aluminium oxide nanoparticles are stable over a wide range of temperatures. Their antimicrobial property is due to their interaction with the cell membrane, resulting in distortion of the cell membrane as well as cell death of bacteria.

Natural occurrence

Corundum is the most common naturally occurring crystalline form of aluminium oxide. Rubies and sapphires are gem-quality forms of corundum, which owe their characteristic colors to trace impurities. Rubies are given their characteristic deep red color and their laser qualities by traces of chromium. Sapphires come in different colors given by various other impurities, such as iron and titanium. An extremely rare, δ form, occurs as the mineral deltalumite.

Properties

Al2O3 is an electrical insulator but has a relatively high thermal conductivity (30 Wm−1K−1) for a ceramic material. Aluminium oxide is insoluble in water. In its most commonly occurring crystalline form, called corundum or α-aluminium oxide, its hardness makes it suitable for use as an abrasive and as a component in cutting tools.

Aluminium oxide is responsible for the resistance of metallic aluminium to weathering. Metallic aluminium is very reactive with atmospheric oxygen, and a thin passivation layer of aluminium oxide (4 nm thickness) forms on any exposed aluminium surface in a matter of hundreds of picoseconds.[better source needed] This layer protects the metal from further oxidation. The thickness and properties of this oxide layer can be enhanced using a process called anodising. A number of alloys, such as aluminium bronzes, exploit this property by including a proportion of aluminium in the alloy to enhance corrosion resistance. The aluminium oxide generated by anodising is typically amorphous, but discharge assisted oxidation processes such as plasma electrolytic oxidation result in a significant proportion of crystalline aluminium oxide in the coating, enhancing its hardness.

Amphoteric nature

Aluminium oxide is an amphoteric substance, meaning it can react with both acids and bases, such as hydrofluoric acid and sodium hydroxide, acting as an acid with a base and a base with an acid, neutralising the other and producing a salt.

Al2O3 + 6 HF → 2 AlF3 + 3 H2O

Al2O3 + 2 NaOH + 3 H2O → 2 NaAl(OH)4 (sodium aluminate)

Applications

Known as alpha alumina in materials science communities or alundum (in fused form) or aloxite[20] in the mining and ceramic communities aluminium oxide finds wide use. Annual world production of aluminium oxide in 2015 was approximately 115 million tonnes, over 90% of which is used in the manufacture of aluminium metal.[7] The major uses of speciality aluminium oxides are in refractories, ceramics, polishing and abrasive applications. Large tonnages of aluminium hydroxide, from which alumina is derived, are used in the manufacture of zeolites, coating titania pigments, and as a fire retardant/smoke suppressant.

Over 90% of the aluminium oxide, normally termed Smelter Grade Alumina (SGA), produced is consumed for the production of aluminium, usually by the Hall–Héroult process. The remainder, normally called speciality alumina is used in a wide variety of applications which reflect its inertness, temperature resistance and electrical resistance.

Fillers

Being fairly chemically inert and white, aluminium oxide is a favored filler for plastics. Aluminium oxide is a common ingredient in sunscreen and is sometimes also present in cosmetics such as blush, lipstick, and nail polish.

Glass

Many formulations of glass have aluminium oxide as an ingredient.[22] Aluminosilicate glass is a commonly used type of glass that often contains 5% to 10% alumina.

Catalysis

Aluminium oxide catalyses a variety of reactions that are useful industrially. In its largest scale application, aluminium oxide is the catalyst in the Claus process for converting hydrogen sulfide waste gases into elemental sulfur in refineries. It is also useful for dehydration of alcohols to alkenes.

Aluminium oxide serves as a catalyst support for many industrial catalysts, such as those used in hydrodesulfurization and some Ziegler–Natta polymerizations.

Gas purification

Aluminium oxide is widely used to remove water from gas streams.[23]

Abrasive

Aluminium oxide is used for its hardness and strength. Its naturally occurring form, Corundum, is a 9 on the Mohs scale of mineral hardness (just below diamond). It is widely used as an abrasive, including as a much less expensive substitute for industrial diamond. Many types of sandpaper use aluminium oxide crystals. In addition, its low heat retention and low specific heat make it widely used in grinding operations, particularly cutoff tools. As the powdery abrasive mineral aloxite, it is a major component, along with silica, of the cue tip “chalk” used in billiards. Aluminium oxide powder is used in some CD/DVD polishing and scratch-repair kits. Its polishing qualities are also behind its use in toothpaste. It is also used in microdermabrasion, both in the machine process available through dermatologists and estheticians, and as a manual dermal abrasive used according to manufacturer directions.

Paint

Main article: Alumina effect pigment

Aluminium oxide flakes are used in paint for reflective decorative effects, such as in the automotive or cosmetic industries.[citation needed]

Composite fiber

Aluminium oxide has been used in a few experimental and commercial fiber materials for high-performance applications (e.g., Fiber FP, Nextel 610, Nextel 720).[24] Alumina nanofibers in particular have become a research field of interest.

Body armor

Some body armors utilize alumina ceramic plates, usually in combination with aramid or UHMWPE backing to achieve effectiveness against most rifle threats. Alumina ceramic armor is readily available to most civilians in jurisdictions where it is legal, but is not considered military grade.[25]

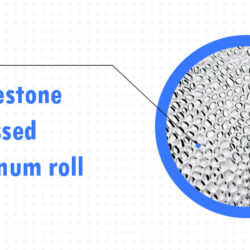

Abrasion protection

Aluminium oxide can be grown as a coating on aluminium by anodizing or by plasma electrolytic oxidation (see the “Properties” above). Both the hardness and abrasion-resistant characteristics of the coating originate from the high strength of aluminium oxide, yet the porous coating layer produced with conventional direct current anodizing procedures is within a 60-70 Rockwell hardness C range [26] which is comparable only to hardened carbon steel alloys, but considerably inferior to the hardness of natural and synthetic corundum. Instead, with plasma electrolytic oxidation, the coating is porous only on the surface oxide layer while the lower oxide layers are much more compact than with standard DC anodizing procedures and present a higher crystallinity due to the oxide layers being remelted and densified to obtain α-Al2O3 clusters with much higher coating hardness values circa 2000 Vickers hardness.