Short for “reinforcing bar,” rebar is refers to metal – usually steel – that’s used to help increase the tensile strength of concrete for a variety of needs, including many of the most common construction types you see every day.

As we noted above, rebar is short for either reinforcing bar or reinforcement bar. While it’s most commonly made from steel, there are other types of metal that may be used also, but the goal is the same regardless: To increase tensile strength in concrete and allow for these structures to withstand bending, torsion and shearing of loads.

Why is this necessary? Well, because concrete is known to be weak in the areas we just mentioned, at least compared to steel and other metal types. If this reinforcement was not used, these structures would at-risk of falling apart.

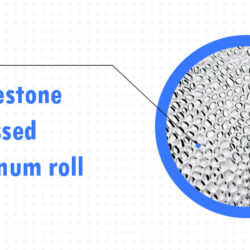

Rebar usually will be built so the metal component is not visible within the structure. Rather, it will be buried within the concrete. It’s usually made with ribs rather than smoothly, allowing it to avoid slippage within its structure.

How Rebar is Made

As we noted above, the most common material for rebar use is steel, which is used because of its excellent tensile properties. It’s often made from forms of recycled steel, which will be melted down using an electric arc furnace, cooled using billets, and then stored until it’s needed.

From here, billets can be reheated to an elevated temperature and fed through extrusion tools, then necked down until its proper size is reached. Finally, it will be tooled to create the proper ribbing, which we noted above is in place to prevent slippage within concrete. Then it will be sheared to the proper length, and it’s ready to go.

Types of Rebar

Here’s a primer on the varying different types of rebar you might find, both in terms of the metal used and some of the additional properties:

Carbon steel rebar: Perhaps the most common type of rebar out there is carbon steel rebar, which is so popular in large part because it’s both strong and affordable. It’s the foundation of many construction-related concrete pours, utilized in numerous buildings and structures all around you.

Stainless steel rebar: While stainless steel shows similar properties to carbon steel, and even improved qualities in a couple areas, it’s less common because of how expensive it is. However, in corrosive environments where zinc is not an option for coating, it’s often used due to its galvanization properties.

Galvanized rebar: In cases where corrosion is possible, the rebar will be put through several processes to apply zinc coating to the surface. The zinc will shield the steel from corrosion risks like rust and others.

GFRP: Short for gas fiber reinforced polymer, GFRP is a fiberglass-reinforced polymer. It has fantastic tensile strength, and is sometimes used as a good alternative to carbon steel.

Epoxy coated reinforced rebar: The most recent form of rebar made for corrosive environments, this type includes a different kind of corrosion protection in the form of epoxy coating.

European rebar: This is actually the same product as rebar found in the US, but it’s measured using different standards. Speak to our team about this if it’s a concern for you.

Specific Benefits/Qualities of Rebar

As we’ve noted above, the primary benefit of rebar is the way it supports concrete during any construction project. Concrete is naturally weaker in certain areas, but supporting it with steel or other metals that are extremely strong and durable will remedy this issue.