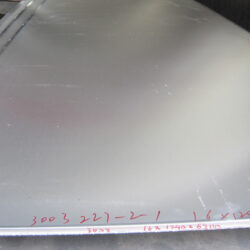

5052 h32 aluminum properties is the most commonly used temper of 5052 aluminum plate. H32 represents the processing status of the 5052 aluminum sheet product. H can be understood as incomplete annealing and work hardening, that is, the product has been annealed, and the hardness has been reduced for processing and forming. At the same time, in order to prevent the hardness of 5052 aluminum alloy is too soft and has been properly work hardened. 32 means that the hardness of the modified product is 1/4 hardness after stabilization treatment. H32 is the annealed state, after work hardening, it is in a 1/4 hard state after stabilization treatment. 5052 H32 aluminum plate can generally meet 90-degree bending and shallow stretching, and the stamping requirements are not cracked.

5052 aluminum plate is an aluminum-magnesium alloy with a magnesium alloy content of around 2.5%. It has been stabilized and processed in a state of incomplete annealing and hardening. It is suitable for chassis cabinets and other classic materials for bending products. According to their use, semi-rigid products of 5052 aluminum sheet mainly include H32 and H22. 5052 alloy H32 state plate, after 140 ℃ / 4h stabilization treatment, can meet the technical conditions, σb reaches 228MPa; δ is 8.5%. The production process flow of H32 state is: smelting – casting – milling – sawing – milling Surface – soaking – hot rolling – cold rolling – re-rolling and trimming + cleaning – intermediate annealing – cold rolling – stabilization annealing – stretch bending and straightening – packaging and delivery.

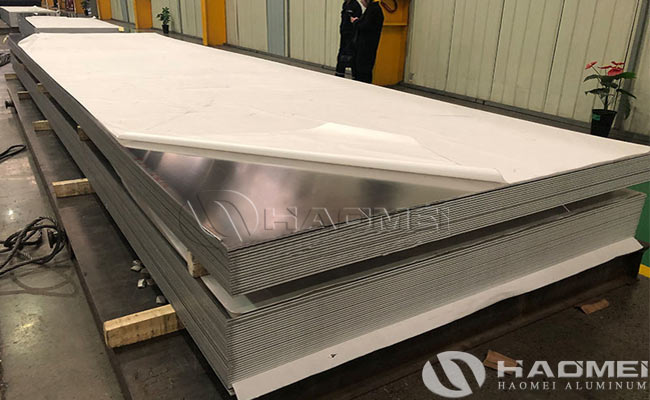

For 5052 h32 aluminum properties, the processing technology is skilled, the product has good forming performance, corrosion resistance, the width of the 5052 aluminum plate produced can reach 2650mm, the thickness can reach 500mm, the production of 5052 aluminum sheet manufacturers, used in silos, flange material, GIS shell, yacht, underwear mold/shoe mold, air tank and machining.