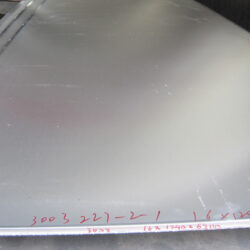

As a typical alloy of 5000 series, the Mg content of 5052 aluminum plate is 2.2%~2.8%. It is a low Mg, non-hardened aluminum plate without heat treatment. It has the characteristics of medium strength, good corrosion resistance, good welding performance, and easy processing and forming. In the annealed state, the alloy has a high rate of work hardening and therefore, in the hard state, its ductility is low. When the cold treatment rate of the sheet after hot rolling is 50%, the recrystallization temperature of the alloy is about 288 °C. Mg is the only strengthening element, which has a certain solid solution strengthening effect, and can increase the work hardening rate of the alloy, so that the alloy can get more obvious strain strengthening. Because 5052 alloy has the advantages of good formability, corrosion resistance, weldability, fatigue strength, etc., it is often used in decorative panel materials.

With the development of related industries such as machinery and automobiles, the demand for 5052 aluminum sheet is increasing. At present, the research on this material mainly focuses on the alloy welding process. Now let’s take a look at the aluminum-magnesium alloy welding characteristics of 5052 aluminum plate:

1, Strong reducing ability.

The affinity between aluminum and oxygen is very strong, and aluminum can easily combine with oxygen in the air to form a dense and strong A1203 film with a film thickness of about 0.1 μm; 600°C). In the welding process, the oxide film will hinder the good bonding between the metals, and it is easy to cause slag inclusions. The aluminum oxide film will also absorb moisture, which will promote the formation of pores in the weld during welding.

2, Higher thermal conductivity and specific heat capacity.

The aluminum 5052 thermal conductivity and specific heat capacity of aluminum and aluminum plates are more than twice those of carbon steel and low-alloy steel. During the welding process, a large amount of heat is rapidly transferred to the inside of the base metal, so when welding aluminum and aluminum plates, the heat is consumed in addition to In addition to melting the metal, more unnecessary consumption is spent on other parts of the metal.

3, Great tendency to thermal cracking.

The linear expansion coefficient of aluminum is about 22.9x 10-6/ ℃, and that of iron is 11.7 x10-6/ ℃. The linear expansion coefficient of aluminum and aluminum plate is about twice that of carbon steel and low alloy steel. The volume shrinkage rate of aluminum during solidification is relatively large, reaching 6.5%, while that of iron is 3.5%. Therefore, shrinkage cavities, shrinkage porosity, thermal cracks and high internal stress are prone to occur when aluminum and aluminum plates are welded.