The most common aluminum alloys are grades of 1060, 1100, 3003, 5052, 5083, 6061, 6082 and 7075 aluminium alloy. We all know that the aluminum alloy has low density, but relatively high strength, close to or surpassing high-quality steel, good plasticity, can be processed into various aluminum materials, has excellent electrical conductivity, thermal conductivity and corrosion resistance, is widely used in industry, and its usage is second only to steel. Some common used aluminum alloys can be heat treated to obtain good mechanical properties, physical properties and corrosion resistance.

The understanding of most common aluminum alloys is a general term for aluminum based alloys. The main alloying elements of aluminum alloys are copper, silicon, magnesium, zinc, manganese, and the secondary alloying elements are nickel, iron, titanium, chromium, lithium, etc. Aluminum alloy is the most widely used non-ferrous metal structural material in the industry, and has been widely used in aviation, aerospace, automobile, machinery manufacturing, shipbuilding and chemical industries. There are 1000 series, 2000 series, 3000 series, 4000 series, 5000 series, 6000 series, 7000 series, 8000 series and 9000 series. Among them, the 1000, 3000, 5000, 6000 series aluminum alloys can be regard as the most common aluminum alloy series. They are widely used in construction, decoration, automobile, electrical, marine industry, aircraft and other industry.

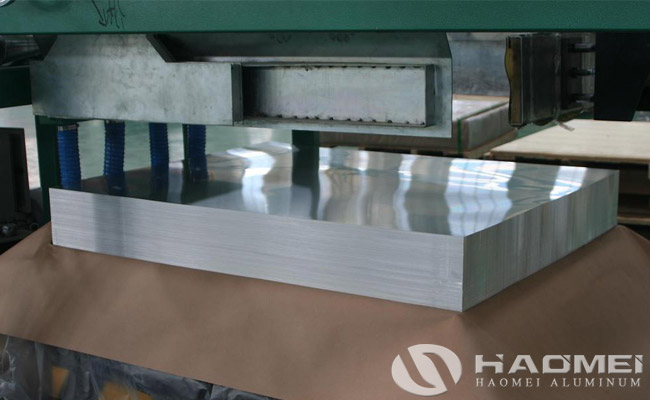

The most common aluminum alloys are: 1060, 1050, 1070, 2024, 1100, 3003, 3004, 5052, 5083, 5086, 5454, 5754, 6060, 6061, 6063, 6082, 7075 and 8011 aluminium alloy. Aluminum and aluminum alloy grades are generally based on the requirements of product use, and the capacity of production equipment to be selected. Requirements for the aluminum sheet alloy are the surface is flat and smooth, the thickness is uniform, the tight iron oxide film is allowed, and there should be no defects such as cracks and scars.