Bismuth is a white, brittle metal with a slight pink color and is typically recovered as a by-product of lead Bismuth is a white, brittle metal with a slight pink color and is typically recovered as a by-product of lead and copper. It is commonly used as an alloying element for various low melting alloys where it is mixed with other metals such as Lead, Tin, or Cadmium. It is also used as well for a lead substitute in other materials. The Needles allow you to have more surface area and pack very tight when melting. They have a purity of 99.9%.

The alloy of bismuth with lead, tin, antimony, indium and other metals is called bismuth alloy. Widely used in printing, cast iron, alarm devices and other aspects.

Classification

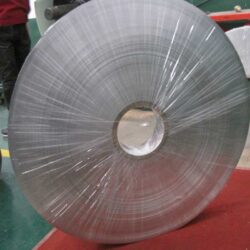

Tin bismuth alloy

Tin bismuth alloy is an environmental friendly alloy. At normal temperature, it is solid, silvery white, with a melting point of 138 ℃, a solid-liquid volume shrinkage of 0.051%, and strong permeability. Low melting point tin bismuth die alloy is used to make cold stamping dies for thin plates. It can press copper, aluminum, steel, stainless steel and other plates. The thickness of the steel plate can reach. Used for stretching, bending and forming thin plates. Using low melting point alloy mold, no mold steel is needed, and the film formation is simple and rapid; Low mold cost and fast update; The mold does not need to be adjusted and processed; The mold can be remelted after use, and the alloy can be reused; Due to the fast molding, the stacking space of the molds can be greatly reduced.

Lead bismuth alloy

Lead bismuth alloys are also known as low-temperature alloys, or low melting point alloys, or fusible alloys. It is mainly composed of lead and bismuth with low melting point, and some other metals are added to adjust the melting point of the alloy. Lead bismuth alloy can be used as a coolant for reactors. Although the melting point of lead bismuth eutectic alloy (LBE) is slightly higher than that of sodium, its chemical activity is weak. Comprehensive performance evaluation and practical engineering applications (including in mobile nuclear power plants) have proved that it is completely feasible to use it as a coolant for the next generation of new fast reactors.

Bi Al alloy

The alloy made of Bi Al is used as the filler for bending thin-walled pipes, which can keep the inner wall of the pipes smooth and smooth, and the filler can be used repeatedly.

A series of low melting point alloys composed of bismuth, cadmium, indium, cadmium and silver are used to make electrical appliances, fuses, automatic device signals, etc. Bismuth tin alloy bullets were used instead of lead bullets.

Characteristic

Bismuth alloy has the property of non shrinkage when solidified, and is used for casting printing type and high-precision mold.

Bismuth alloy is often used as an additive for cast iron, steel and aluminum alloy to improve the cutting performance of the alloy. Bismuth alloy containing 11% antimony is used to manufacture infrared detectors. Bismuth tin and bismuth cadmium alloys are used to manufacture auxiliary electrodes for selenium rectifiers.

A magnetometer is made by using the characteristic that the resistivity of bismuth decreases sharply under the action of a magnetic field. Bi Mn alloy can be used as permanent magnet material. Bismuth has a small thermal neutron absorption cross-section, a low melting point and a high boiling point, and can be used as a heat transfer medium for nuclear reactors.

Bismuth telluride is widely used to manufacture temperature difference elements for solar cells, and bismuth telluride can greatly improve the operating speed and efficiency of computer chips.

Bismuth silver cesium alloy can be used to make photoelectric amplifiers, silver bismuth sulfide can be used to make semiconductor instruments, and bismuth cadmium temperature difference elements can be used for alarm devices.

Application

Safety plugs used for fire-fighting devices, automatic sprinklers and boilers. In case of fire, the pistons of some water pipes will “automatically” melt and spray water.

In the fire protection and electrical industry, it is used as automatic fire extinguishing system and electrical fuse and solder. The bismuth alloy has a property of not shrinking during solidification,

It is used for casting printing type and high-precision mold. Bismuth oxycarbonate and bismuth oxynitrate are used to treat skin injuries and gastrointestinal diseases.

It is used to make low melting alloy and has special importance in fire protection and electrical safety devices.

It is used to detect Mn in analytical chemistry. Bismuth can be used as a low melting point alloy for automatic shutters or movable type alloys.